Symptoms of a bad throttle position sensor

1. Your check engine light is on. The engine’s computer has built-in logic that monitors the TPS feedback to make sure it matches up with information sent by other engine sensors. A faulty TPS can set a trouble code in the computer if the voltage value is either not present, sporadic, slow or constant, and this can illuminate your check engine light.

2. Your engine has little or no acceleration. If the TPS fails to send the proper data back to the computer, the correct fuel calculations can’t be made. With some engines, other sensors are able to compensate and provide a guess at how much fuel is needed, but this usually causes the engine to accelerate poorly or sporadically. In other instances, the car will not accelerate at all.

3. Your car bucks or jerks violently. TPS units sometimes fail in a way that causes the voltage signal sent back to the engine’s computer to be sporadic. This can feel like you are quickly applying and releasing the gas pedal.

4. Your engine surges and stalls out. A failing TPS can cause the engine to search for an idle or surge. This is most noticeable when at idle, when on the highway with the cruise control set, or when keeping the throttle steady with your foot. You will notice your RPM gauge fluctuating up and down quickly or hear the engine revving up and down on its own. If not repaired immediately, this can eventually cause the engine to die out.

5. Your engine starts and dies immediately. A failing TPS can cause a condition where your engine starts, runs briefly, but then dies out. In some cases, you can keep the car running by pressing the accelerator pedal down slightly, but this isn’t recommended.

6. You start getting worse fuel economy. Sometimes a TPS can fail slowly over time and report a slightly incorrect value to the computer. This isn’t enough to set off a check engine light or cause a noticeable running issue, but can contribute to poor fuel economy.

7. Your car goes into limp-home mode. In some cases, a failing or faulty TPS can cause the engine to go into what’s called limp-home mode. This is a safety feature that recognizes a faulty sensor that could cause damage to the engine or drivetrain. In this situation, you will experience reduced engine power, and you may be stuck in a higher gear. This will get you off the highway and allow you to drive a few miles to a repair facility, but you shouldn’t drive any more than needed. A check engine light will be illuminated in this mode as well.

Get it diagnosed by a professional

Throttle position sensor repair advice

A throttle position sensor is not a maintenance item and doesn’t have a specific service interval. The average lifespan of a throttle position sensor is just over 80,000 miles, though some will last for the lifetime of the car.

If a TPS is suspect, a professional repair facility will perform electrical testing on the sensor. A scan tool can also display live data showing how the sensor is performing and sometimes determine if it's faulty.

The cost of replacement can vary greatly. Some can be more difficult to replace, which will affect labor costs. Newer cars also tend to have a throttle setup that is trickier to work on, and a TPS that is pricier to replace.

The TPS is specific to each make and model, and high-quality replacement parts from the original manufacturer are highly recommended. This is a very important sensor on your engine and you shouldn’t take a chance with a cheaper part that may fail quickly or without warning.

If you do it yourself

Replacing the TPS can be straightforward, depending on the model, but the hardest part of the procedure is the diagnosis. If you don’t have the proper diagnostic equipment, it can be cheaper and easier to let a professional work on it.

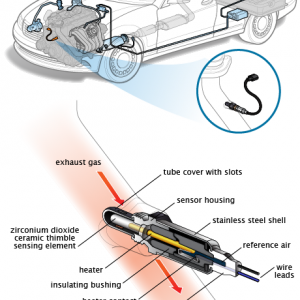

The TPS is a small sensor that's about the size of your key fob. It has an electrical connector attached to it that normally houses three wires. On most engines, there are two smaller screws that secure it to the throttle body.

Since other sensor failures can behave like a faulty TPS, it’s important that you follow proper diagnostic steps. This includes locating the correct wires for electrical testing and knowing the factory specifications of voltage input and output. A hand-held scanner that shows live sensor values is a great tool for TPS diagnosis. Always inspect the wiring and the connector going to the TPS for damage, as that can cause issues consistent with a failed TPS.

If you have determined you have a faulty TPS, you must pay attention to which style of sensor you have. Some older cable-actuated throttle bodies have separate throttle position sensors that must be adjusted before installation. Failure to do so will result in poor performance, incorrect idle RPM and unpredictable throttle response. You can tell if you have an adjustable TPS if there are slots instead of fixed holes for the mounting screws to go through.

Some TPS units are held in with tamper-proof Torx screws. These are Torx screws with a center tab and will not work with normal Torx bits. You will need a tamper-proof Torx bit to remove these screws. Do not over-torque these screws. They require a very minimal amount of torque and can break easily.

If your TPS sensor has turned on the check engine light, you may need to clear it with a scanner. The check engine light will not always go away after replacement of the TPS.

How a throttle position sensor works

The TPS monitors the position of the throttle valve, which regulates how much air is supplied to the engine. Your gas pedal is attached to the the throttle valve (either electronically or mechanically) — as you press the pedal farther in, the valve opens more. The TPS reports the position of the throttle valve to your engine’s computer.

The TPS also relays information to your anti-lock braking system so that it can supply the traction aids your car needs at a given speed. Most engines use only one TPS, but more complex engines may have multiple sensors.

The engine’s computer starts by sending a set amount of voltage to the TPS. There, the TPS applies a certain amount of resistance, depending on how open the throttle valve is, and sends the altered voltage back to the computer. As the throttle valve is opened and closed, that voltage changes.

The engine’s computer uses this and other information to calculate the proper amount of fuel, ignition timing and in some cases camshaft timing needed to run the engine efficiently.